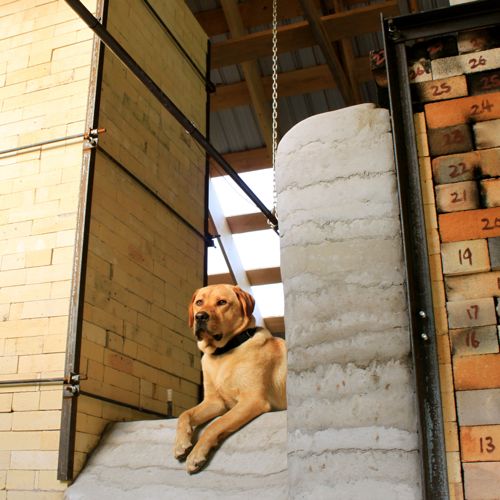

unloading

The day of the unloading began with a few preparatory tasks, namely cleaning up and numbering the door bricks for an easy stack-up next time. Not so long ago, I might have rushed to take down the doors, pulled out everything, and then been faced with a giant mess to clean up . . . but three years of kiln building and a very methodical partner have had a good influence . . . namely in the form of patience! We even vowed to clean and grind kiln shelves and posts as we went; four shelves of pots to unload, four to grind. Nonetheless, there was a definite sense of excitement as we took out the bricks and got our first good glances.

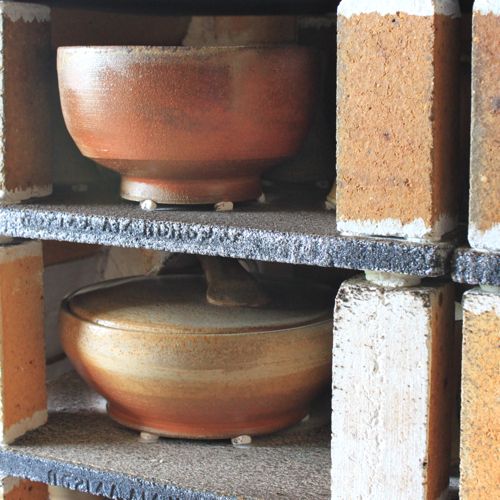

Holding our breath . . . our first reactions were mixed . . . initially the pottery looked OK, if a bit on the pale side. (We do tend to prefer lighter tones from the wood kiln as opposed to dark browns, so this was at least visually unobjectionable.) What we quickly realized, though, was that most of what we found in the middle of the kiln was dry. Under-fired. Too crusty, and perhaps not even water-tight. Ugh.

The good side of all this was that not too much was ruined! In fact, in the first couple hundred pots that we pulled out, only three ended up in the wheelbarrow. The bad news was that only three ended up on the table of work to actually sell. The vast majority of the work we found in the first chamber was destined to be re-fired. (All you potters out there, we think 'too cool' in this case was about cone 8 or so.)

At least we're a few hundred pieces closer to our next firing!

We continued on like this for almost an entire day, filling up the tables with pieces to be re-fired. We took a quick trip to the river for a bit of helpful perspective, no doubt feeling a little down, but heartened somewhat by the fact that we didn't find any major disasters, and that the flashing and ash colors looked pretty nice, for the most part, knowing it just needs more heat!

Why didn't we keep firing if it was so cool? The cones in front of the kiln showed cone 12, and the stack just behind was not far behind. We didn't want to risk over-firing the front, but in retrospect, we should have kept firing and sacrificed a few pieces in front for the good of the rest of the kiln. We also hoped our side-stoking efforts would even things out, but we just didn't stay hot-enough for long enough. The biggest thing we struggled with during the firing was the un-eveness of temperatures from front to back, top to bottom. Our chimney is HUGE, which means it pulled much of the heat across the floor and out the stack, even with the dampers at 10%! Also, our burn was very, very efficient with all the built-in air channels, so much of the chamber was oxidized as we missed out on a lot of the reduction cycles that contribute to richer colors.

At nearly 6pm on the first day, Nathan decided it was time to take down the door to the soda chamber. We were hoping we would see something to lift our spirits. (I can't believe we hadn't opened it yet!) And we found beauty . . . ahhh. We each took a deep breath of relief to find gorgeous flashing slips, melted glaze, and lovely effects from the soda. Most of what we could see looked really nice- we felt saved by the soda chamber!

With that good news, we called it a night. Back at work the next morning- already 92 degrees at 8am- we finished unloading the rest of the first chamber, and found a few gems in the rough. Some places were hot enough to melt the ash on the surfaces (that is, if the pieces hadn't cracked)- the very front stack had some nice ones, and the areas around the flues at the back of the chamber were lovely, too.

We started in earnest unloading the soda chamber in the extreme heat. We found lots of beauties- finally some ware boards of pottery ended up on the 'to sell and photograph' table! The melt was good, and while the chamber wasn't without issues of its own, we had a much better success rate overall.

The nice pottery we found made clean-up a little easier. The kiln itself fared pretty well, just a few bricks out of place in the main firebox. The castable fired to a very pretty pure white and held up beautifully while the bricks took on a toasty glow. Overall, the shelves cleaned up fairly easily, thanks to some grinding bricks and a diamond cup attachment for the angle grinder. There were some big nasties in the soda chamber, especially the soda that accumulated on the false floor (i.e. removable!!) that Nathan put in pre-firing. (Can you believe that gnarly situation?!? And no, he did not intend to match the color with his shirt.)

We are hoping and scrambling planning to fire again in a month, before our biggest show of the year. We have a new road map, changes planned, and a lot to do . . . and are already excited to try this again!

~Becca

Next up: A proper photo shoot of the newest work, and hopefully a select few posted to our online shop soon.